Portal frame pressure plate chute block sensor

Details:

Details:

The equipment is installed to inspect the chute block fault in the belt transportation system. The shutdown alarm should be sent when the equipment detects the block fault in the chute so as to prevent the occurrence of vicious accident caused by the blocked material.

Working

(1) LDM-Z Chute Block Sensor

It is designed with portal frame based on the travel-switch principle: when material block occurs in the chute, the block should push the active door moving backward to press the travel-switch to sent out the alarm and shutdown signal. And the active door should be reset by the gravity once the block fault is eliminated.

(2) LDM-T Chute Block Sensor

It is designed with portal frame and spring-restoration function, and is installed on sidewall of the chute. There is a sealed protective travel-switch inside. When material block occurs, the block should press the sidewall so as to push the active door of the sensor moving outward. Once the deflection angle is bigger than the limited angle, the travel-switch should be touched and the sensor will sent out the alarm and shutdown signal. The sensor can also be installed in the control circuit with vibrators to achieve automatic fault elimination without shutdown if the chute is slightly blocked. The active door should be reset once the block fault is eliminated.

(3) Installation Method

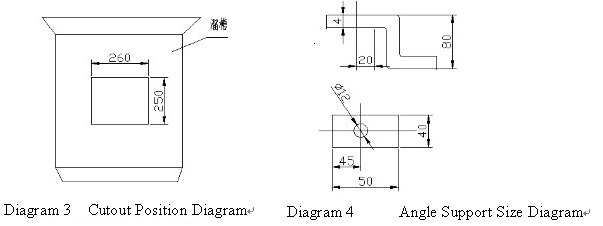

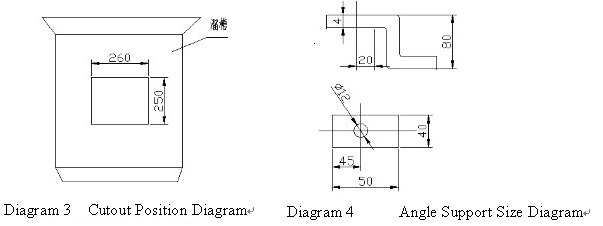

i. As the Diagram 1 shown, open a cutout on the chute (see Diagram 3), weld a 300mm plate on the inner wall above 100~200mm from the cutout to prevent the large materials mis-impacting the active door in the sensor. ii. Cusomers can also weld an angle support (see Diagram 4) on the sidewall of the chute, fixed with bolts or welding.

(4)Attention

i. 2 of the sensors could be a group, respectively installed on the sidewalls where relatively hardly or slightly be impacted by the materials. The installation height is based on the requirement of customers. (usual height: 2/3 height of the chute from bottom.) ii. Customers also could use 4 sensors as 2 groups. 1 is installed on the sidewall at the position of 1/3 height of the chute from the bottom as slight block inspection which only sends out the alarm signal; the other is installed at the position of 2/3 height of the chute from the bottom as severe block inspection which sends out shutdown signal when block occurred.

(5) Wiring

Red and Yellow is as a group for NC ( Normally Closed), Yellow and Blue is as a group for NO (Normally Opened).